Cordite

paste drying and pressing:

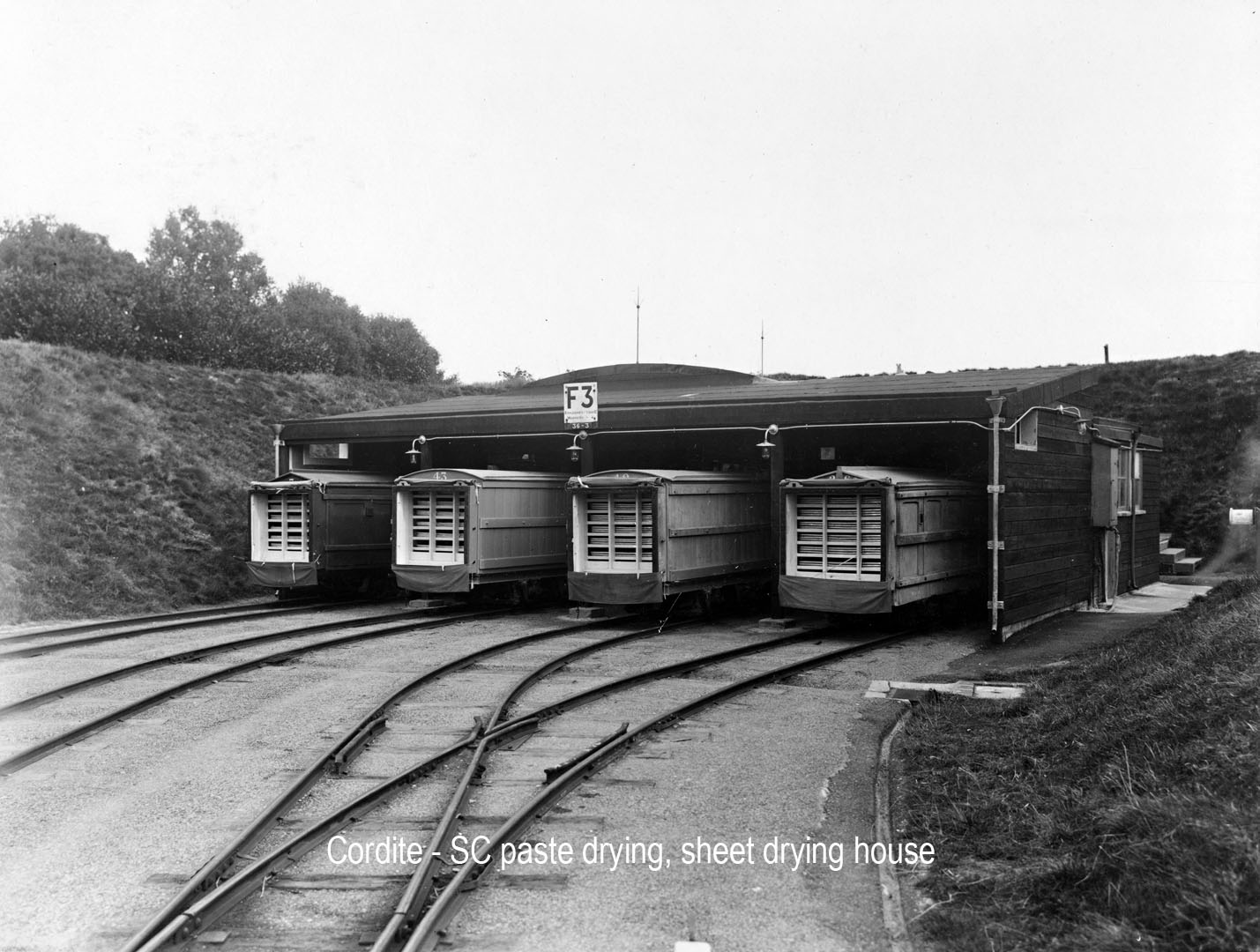

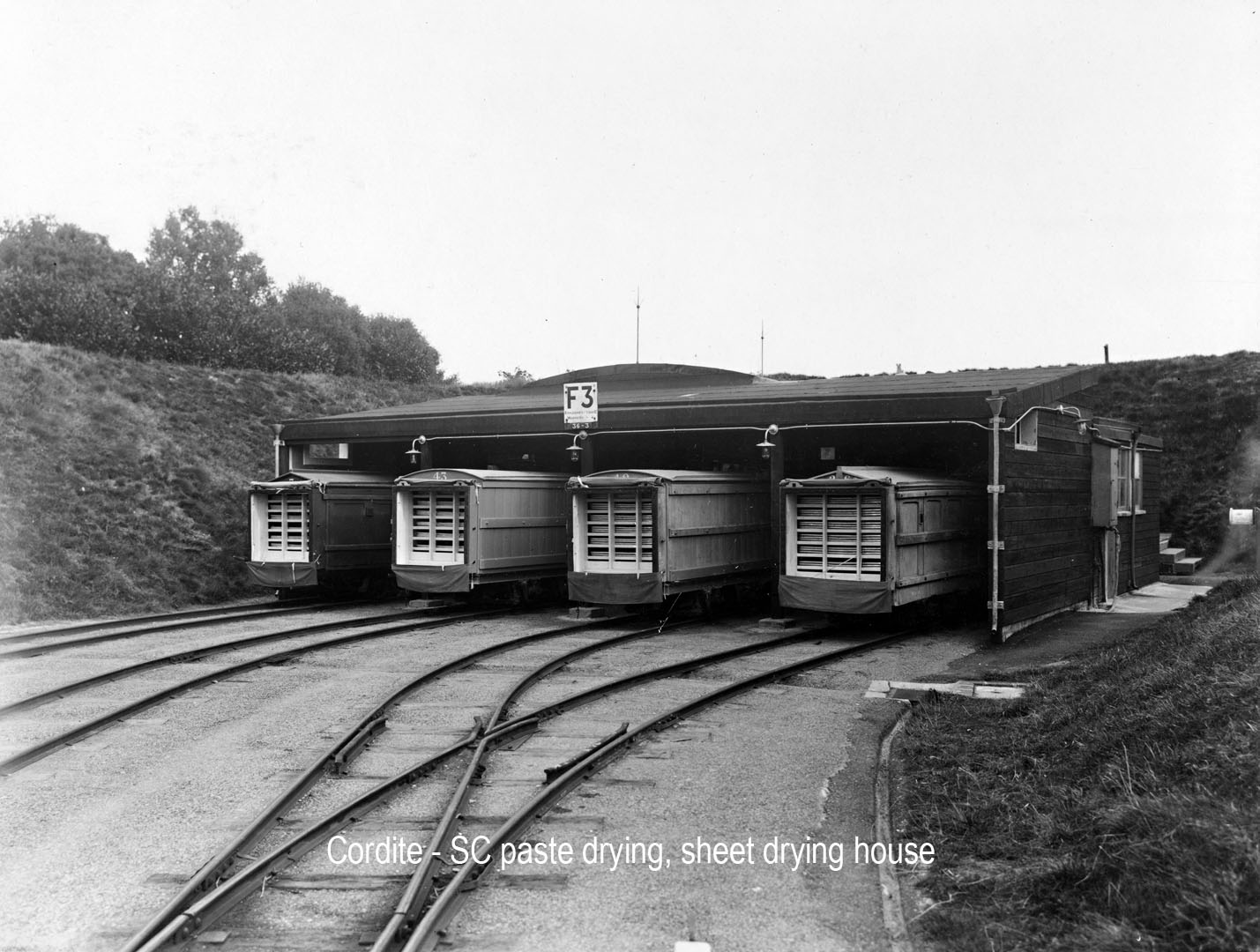

The paste sheets were dried with a current of warm air in special

trucks designed for the purpose, which could be coupled into a hot-air

system.

A typical paste drying stove is shown below:

After drying, the paste was installed in an incorporator, where any

additives/solvents were included. The 'incorporator' was in fact, an

adapted dough-making machine. During this process, the mixture became

gelatinised.

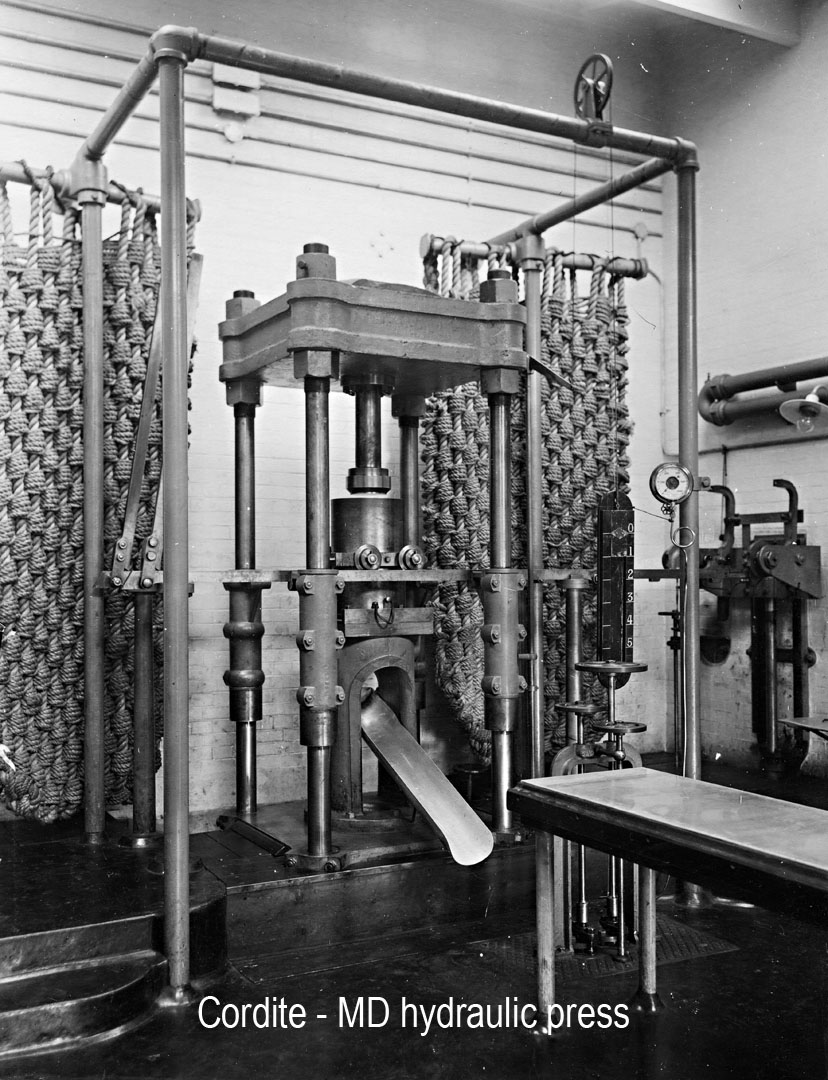

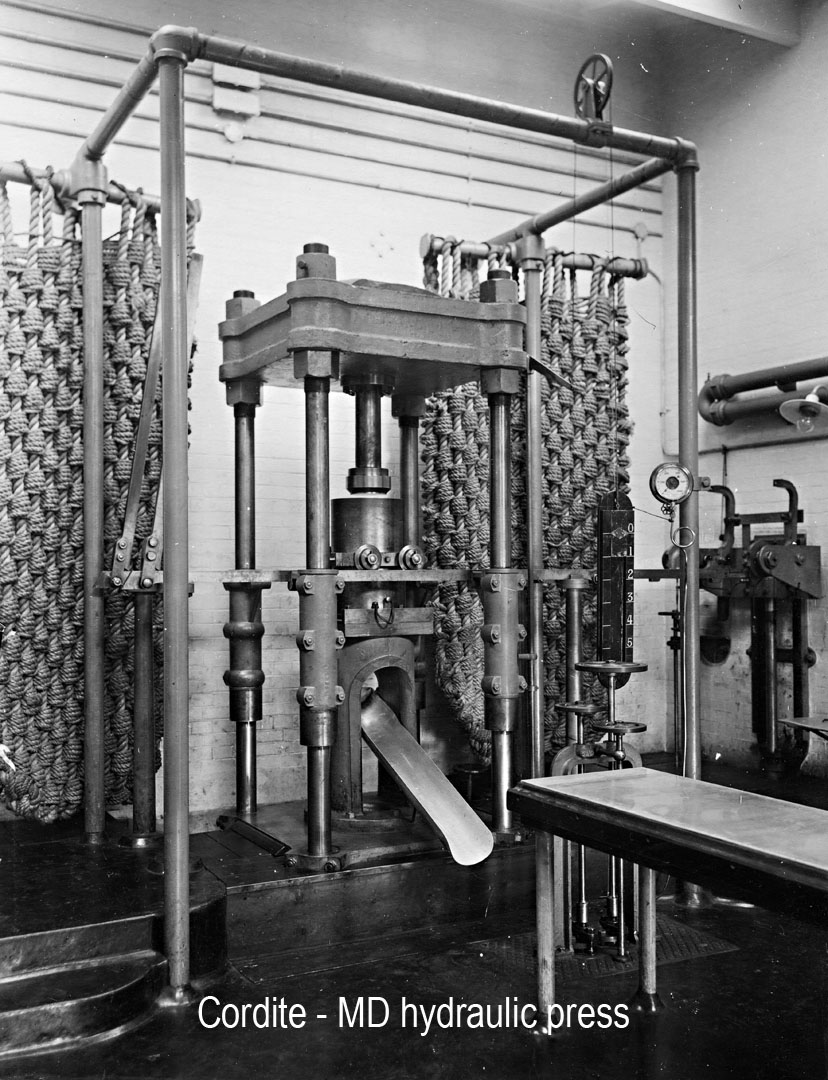

Finally, the cordite was rolled and/or pressed into the required shape

- some uses required the traditional long cords (from which the name

arises), others required large blocks for assisted aircraft take-off

systems for example. This required a number of hydraulic presses which

of course differed greatly in size and shape. See two examples below:

Horizontal press for large-diameter cordite.

Vertical press for traditional cordite.