The Nitration processes.

Cordite (propellant) is a basic mixture

of two explosives; Nitroglycerine and Nitrocellulose. Some

additives/stabilisers are also included.

The process of cordite manufacture begins with the nitration of glycerine and cellulosic material to produce nitroglycerine and nitrocellulose. In both cases the base material is reacted with a mixture of nitric and sulphuric acids. The reaction (which is exothermic) is cooled by circulation of chilled brine as required.

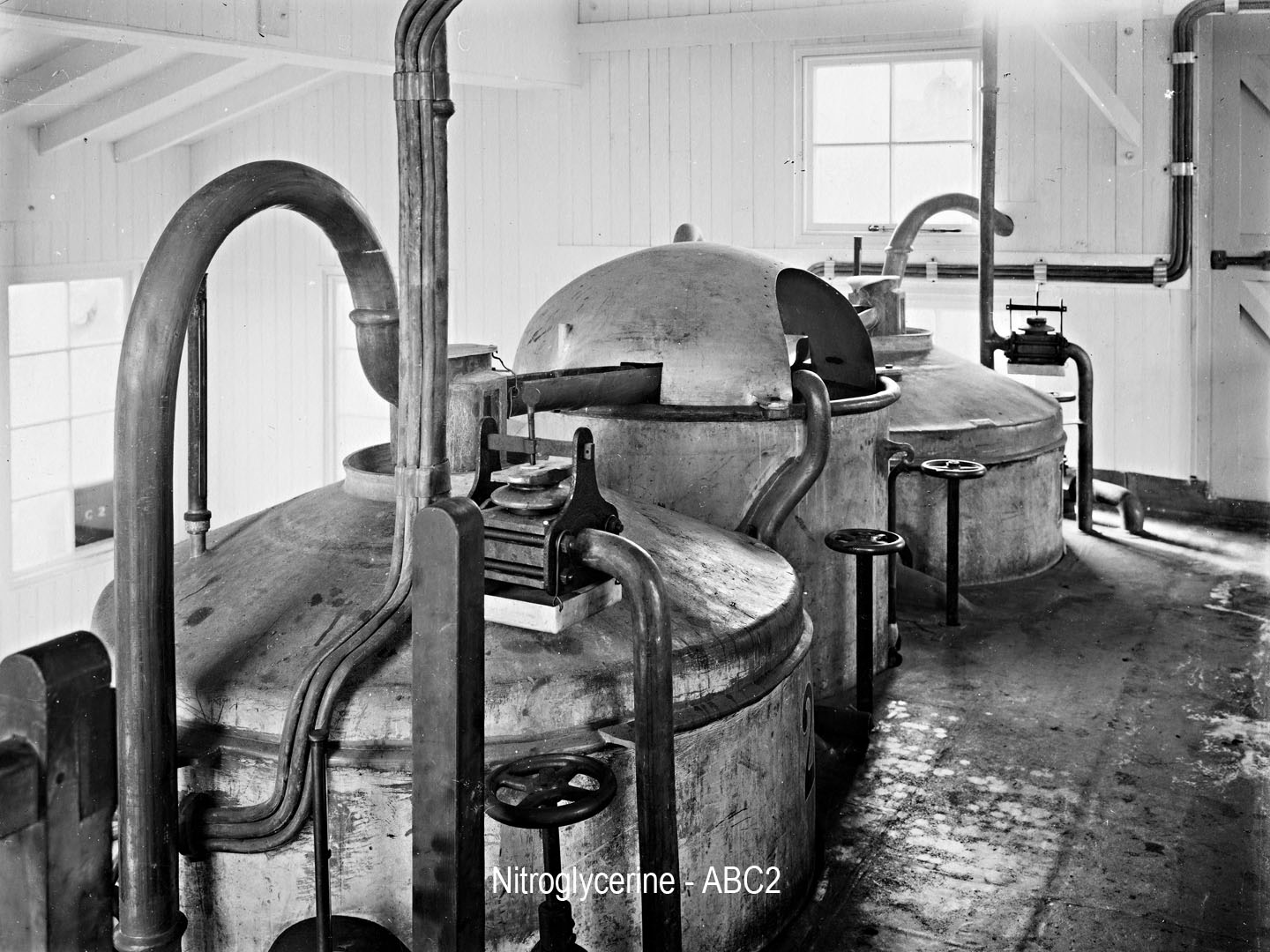

Starting with Nitroglycerine, two types of nitrator were in use at Holton Heath; The Batch process (Nathan-Thomson-Rintoul) and the Schmid continuous system.

Below left, a view inside the batch nitrator, showing nitration

vessels and separator:

The process of cordite manufacture begins with the nitration of glycerine and cellulosic material to produce nitroglycerine and nitrocellulose. In both cases the base material is reacted with a mixture of nitric and sulphuric acids. The reaction (which is exothermic) is cooled by circulation of chilled brine as required.

Starting with Nitroglycerine, two types of nitrator were in use at Holton Heath; The Batch process (Nathan-Thomson-Rintoul) and the Schmid continuous system.

Below left, a view inside the batch nitrator, showing nitration

vessels and separator:

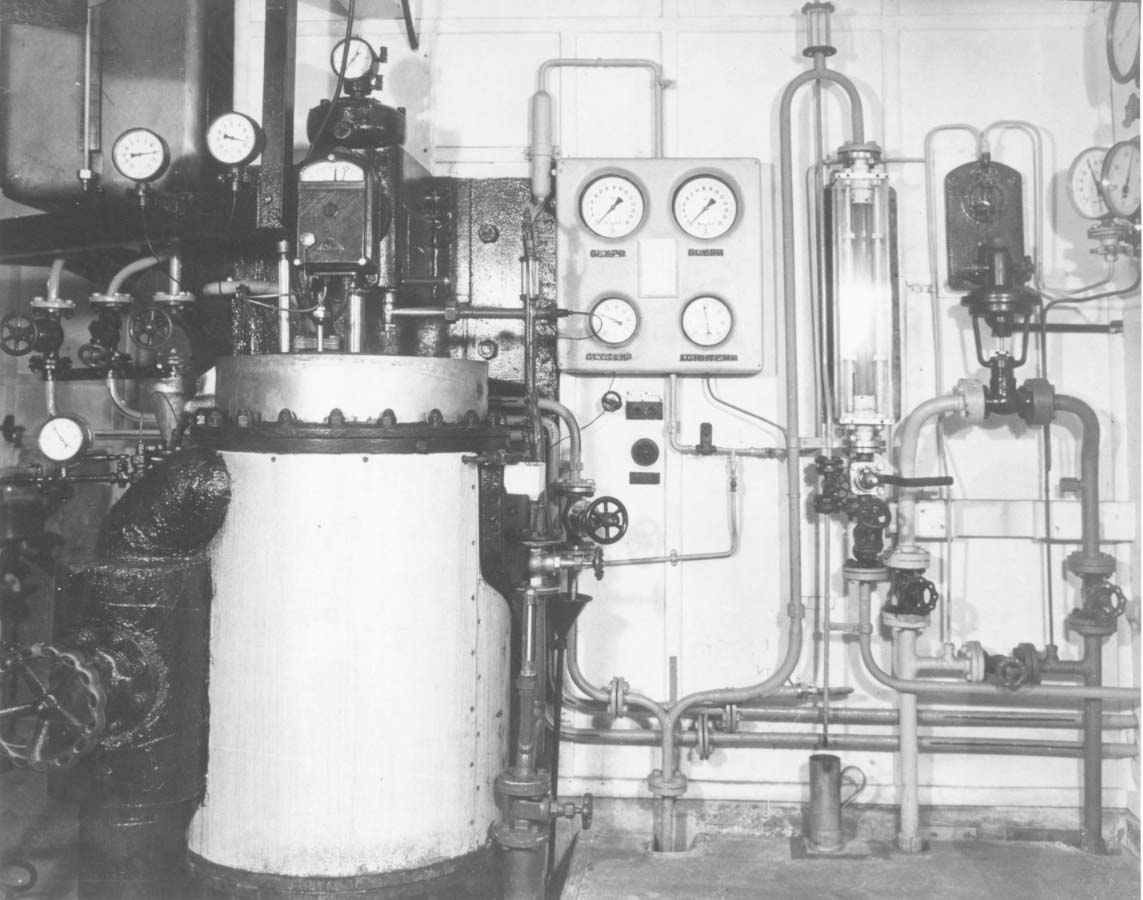

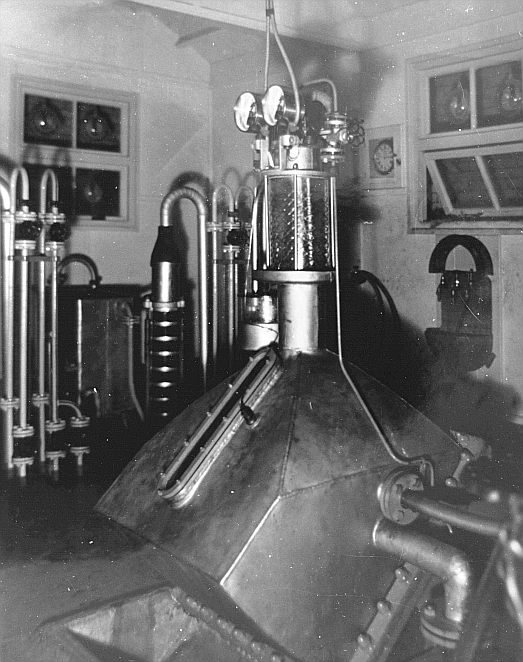

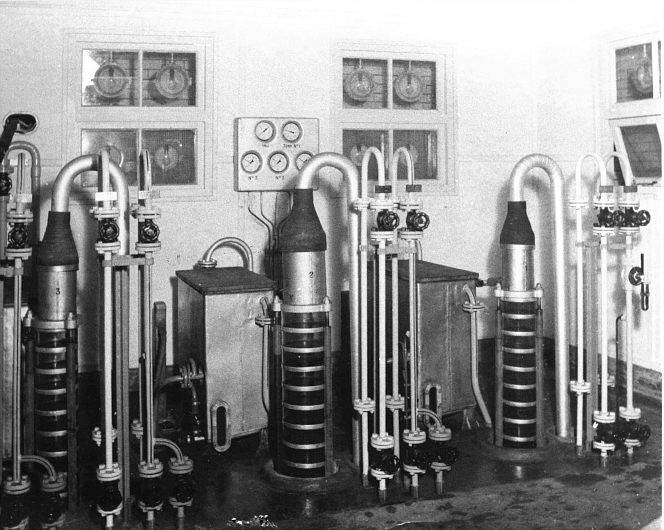

Above,

The Schmid continuous nitrator.

The Schmid

separator.

Nitrocellulose: This was originally made from cotton to form guncotton, but later the factory employed scrolled paper as the cellulosic input.

Below is a view inside the nitrocellulose factory, showing the pans where mixed acid was introduced to the cotton or paper:

Nitrocellulose: This was originally made from cotton to form guncotton, but later the factory employed scrolled paper as the cellulosic input.

Below is a view inside the nitrocellulose factory, showing the pans where mixed acid was introduced to the cotton or paper:

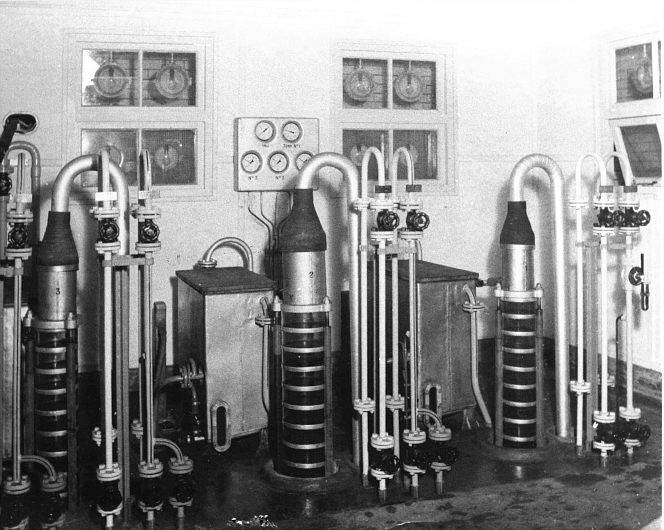

The nitroglycerine washing columns

(Schmid

unit)